Industrial Bulk Packaging Market Size to Worth USD 38.83 Bn by 2033

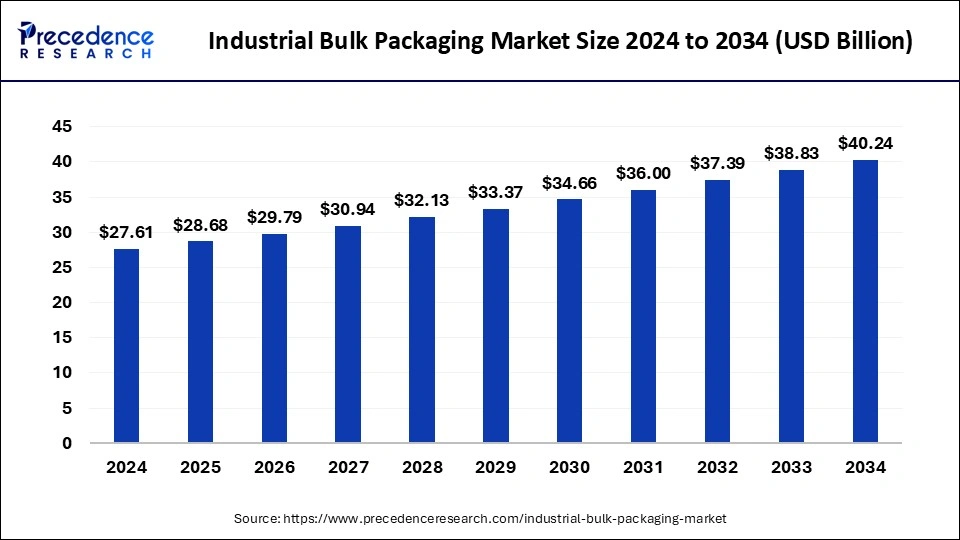

The global industrial bulk packaging market size is expected to increase USD 38.83 billion by 2033 from USD 26.59 billion in 2023 with a CAGR of 3.86% between 2024 and 2033.

Key Points

- Asia Pacific dominated the market with the largest revenue share of 39% in 2023.

- By product, the drums segment has held a major revenue share of 48% in 2023.

- By application, the chemicals & petrochemicals segment dominated the market in 2023.

The industrial bulk packaging market encompasses a wide range of packaging solutions designed for transporting and storing large quantities of goods across various industries. These packaging solutions are crucial for safely handling bulk materials such as chemicals, food ingredients, pharmaceuticals, and construction materials, among others. They ensure efficient logistics and reduce handling costs throughout the supply chain.

Get a Sample: https://www.precedenceresearch.com/sample/4546

Growth Factors

The industrial bulk packaging market is experiencing robust growth driven by several key factors. One of the primary drivers is the increasing globalization of supply chains, which demands efficient and secure transportation of bulk goods. Moreover, the rise in industrial activities, particularly in emerging economies, has escalated the demand for reliable and cost-effective packaging solutions. Additionally, advancements in packaging materials and technologies are enhancing the durability, sustainability, and performance of bulk packaging, further fueling market growth.

Regional Insights

Geographically, the industrial bulk packaging market shows varying trends across regions. North America and Europe are mature markets with a strong emphasis on technological advancements and sustainability in packaging solutions. Asia-Pacific, led by countries like China and India, is witnessing rapid industrialization and infrastructure development, driving significant demand for bulk packaging solutions. Meanwhile, Latin America and the Middle East & Africa regions are experiencing steady growth, supported by expanding industrial sectors and increasing trade activities.

Trends

Current trends in the industrial bulk packaging market include the adoption of eco-friendly materials and designs to meet stringent environmental regulations and sustainability goals. There is also a growing preference for flexible and customizable packaging solutions that cater to diverse industry needs. Moreover, digitalization and the integration of smart technologies are transforming bulk packaging with innovations such as RFID tracking and real-time monitoring, enhancing supply chain visibility and efficiency.

Industrial Bulk Packaging Market Scope

| Report Coverage | Details |

| Market Size by 2033 | USD 38.83 Billion |

| Market Size in 2023 | USD 26.59 Billion |

| Market Size in 2024 | USD 27.61 Billion |

| Market Growth Rate from 2024 to 2033 | CAGR of 3.86% |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | Product, Application, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Industrial Bulk Packaging Market Dynamics

Drivers

Key drivers influencing the industrial bulk packaging market include the need for safe and secure transportation of bulk goods, cost-effectiveness in logistics operations, and regulatory compliance regarding product safety and handling. Additionally, the demand for lightweight and recyclable packaging materials is driven by sustainability initiatives across industries.

Opportunities

The market presents several opportunities for growth, particularly in developing regions where infrastructure investments and industrial expansions are driving increased demand for bulk packaging solutions. Innovations in packaging designs and materials offer opportunities for manufacturers to differentiate their products and cater to specific industry requirements. Furthermore, collaborations and partnerships across the supply chain can lead to enhanced distribution networks and market penetration.

Challenges

Despite its growth prospects, the industrial bulk packaging market faces challenges such as fluctuating raw material prices, stringent regulatory requirements, and the need for continuous innovation to meet evolving customer expectations. Additionally, ensuring compatibility with diverse types of bulk materials and maintaining product integrity during transportation remain critical challenges for stakeholders in the market.

Read Also: Command and Control Systems Market Size, Growth, Report by 2033

Industrial Bulk Packaging Market Companies

- BWAY Corporation

- Cleveland Steel Container

- Composite Containers LLC

- Eagle Manufacturing Company

- Grief

- Hoover Ferguson Group, Inc.

- International Paper

- Myers Container

- Time Technoplast Ltd.

- Peninsula Drums

Recent Developments

- In June 2024, Coveris, an international packaging company signed the partnership with the Interzero, environmental service providing company for developing new strategies for innovative plastic recycling, waste management and providing the closed-loop solutions for packaging industries. This partnership between the Coveris company, manufacturer of packaging and Interzero, the supplier of circular economy services and experts in sorting and recycling plastics represents a critical turning point in the closing of the loop in plastics recycling, assisting both businesses in their committed goal of eradicating waste in all of its forms. With the introduction of ReCover, a cutting-edge waste recycling method that promotes the circular economy for plastics, Coveris has already made significant progress toward realizing its “No Waste” objective. Coveris’ ReCover companies will now process the materials that Interzero gathered and sorted, resulting in the production of superior recycled resins by mechanical recycling that surpasses current market standards in quality. Afterwards, Coveris’ high-performance packaging goods, like Duralite R collation films, will make use of these resins.

- In June 2024, Parkside, privately held packaging company, revealed the expansion of its product portfolio by the introduction of the sustainable flexible packaging options with the recyclable metallised barrier paper solution. The new recyclable metallised barrier paper solution launched by the Parkside company is suitable for wide range of non-food and food application and is primarily used for products such as healthcare items, coffee and snacks.

- In June 2024, Univation Technologies, LLC, a company that supplies polymerization catalysts announced the launch of the licensed technology “Unigility Tubular High-Pressure Polyethylene (PE) Process Technology platform. The newly launched platform by Univation Technologies, LLC company enables production of the ethylene-vinyl acetate (EVA) copolymer resins and low-density polyethylene (LDPE). In addition, licensees can engage in important ethylene-vinyl acetate (EVA) end-use applications in the food and industrial packaging market segments, such as flexible hosing, greenhouse films, cereal liners, fresh meat, photovoltaics, footwear components, and cereal liners and cheese barrier packaging, due to Univation Technologies, LLC company’s UNIGILITYTM Tubular High Pressure Polyethylene (PE) Process Technology.

Segment Covered in the Report

By Product

- Drums

- IBC

- Pails

- Totes/ Cracks

- Others

By Application

- Chemicals & Petrochemicals

- Food & Beverages

- Pharmaceuticals

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.uswebwire.com/