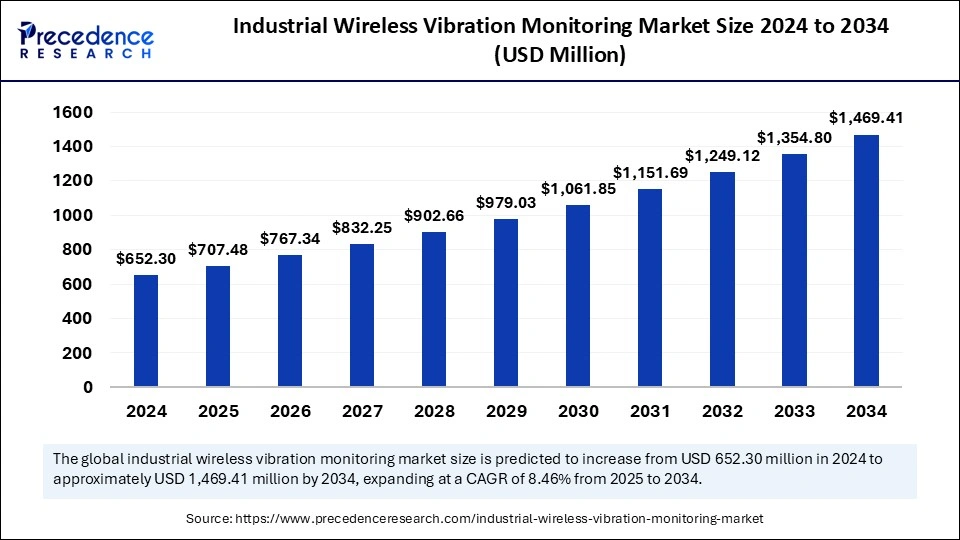

The Industrial Wireless Vibration Monitoring Market size is forecasted to hit USD 1,469.41 million by 2034.

The global industrial wireless vibration monitoring market is forecasted to rise from USD 652.30 million in 2024 to around USD 1,469.41 million by 2034, growing at a CAGR of 8.46%.

Industrial Wireless Vibration Monitoring Market Key Insights

- North America dominated the market by holding 36% of market share in 2024.

- Europe is expected to witness the fastest growth in the coming years.

- By type, the wireless sensors segment held the biggest market share of 37% in 2024.

- By type, the data acquisition systems segment is projected to grow at the fastest rate during the forecast period.

- By application, the condition monitoring segment contributed the highest market share of 42% in 2024.

- By application, the predictive maintenance segment is anticipated to grow rapidly during the projection period.

The industrial wireless vibration monitoring market is witnessing significant growth due to the increasing demand for predictive maintenance and real-time asset monitoring in industries such as manufacturing, oil & gas, energy, and automotive. Wireless vibration monitoring systems help detect equipment failures before they occur, minimizing downtime and reducing maintenance costs. Unlike traditional wired systems, wireless solutions offer greater flexibility, scalability, and ease of installation, making them highly suitable for industries with complex machinery and remote operations. With advancements in Industrial Internet of Things (IIoT) and artificial intelligence (AI)-driven analytics, the market is poised for substantial expansion over the coming years.

Sample Link: https://www.precedenceresearch.com/sample/5692

Market Drivers

Several key factors are driving the growth of the industrial wireless vibration monitoring market

- Growing Demand for Predictive Maintenance – Industries are increasingly shifting from reactive to predictive maintenance to enhance operational efficiency and reduce unexpected downtime. Wireless vibration monitoring plays a crucial role in this transition.

- Advancements in IIoT and Industry 4.0 – The adoption of IIoT and Industry 4.0 technologies is driving the demand for smart sensors and wireless monitoring solutions that enable real-time asset tracking and predictive analytics.

- Increased Focus on Workplace Safety – Monitoring vibrations helps prevent mechanical failures that could lead to hazardous incidents, improving workplace safety in industries such as oil & gas, mining, and manufacturing.

- Cost Efficiency and Ease of Installation – Wireless vibration monitoring systems eliminate the need for extensive cabling and infrastructure, reducing installation and maintenance costs.

- Rising Adoption in Remote and Hazardous Locations – Many industries, including offshore oil rigs and mining sites, require wireless solutions due to their ability to monitor equipment in hard-to-reach locations.

Opportunities

The market presents several opportunities for growth and innovation

- Integration with AI and Machine Learning – AI-driven predictive analytics can enhance vibration monitoring accuracy, enabling early detection of machine faults and optimizing maintenance schedules.

- Expansion in Emerging Markets – Developing countries are increasingly adopting industrial automation, creating opportunities for wireless vibration monitoring solutions.

- Development of Energy-Efficient and Self-Powered Sensors – Innovations in low-power and self-powered wireless sensors can reduce the need for frequent battery replacements, making systems more reliable.

- Adoption in Small and Medium Enterprises (SMEs) – As costs decline, SMEs can increasingly adopt wireless vibration monitoring solutions to improve equipment reliability and reduce operational costs.

- Collaborations and Strategic Partnerships – Companies can expand their market presence through collaborations with industrial automation firms, sensor manufacturers, and cloud service providers.

Challenges

Despite its advantages, the market faces several challenges

- High Initial Investment – While wireless systems are cost-effective in the long run, the initial investment in hardware, software, and integration can be a barrier for some companies.

- Data Security Concerns – As wireless monitoring relies on connected networks, cybersecurity threats pose a risk to data integrity and operational security.

- Limited Battery Life of Wireless Sensors – Frequent battery replacements can lead to increased maintenance efforts, especially in industries with extensive monitoring requirements.

- Connectivity and Interference Issues – Wireless systems may face connectivity issues in industrial environments with high electromagnetic interference or harsh conditions.

- Lack of Skilled Workforce – Effective implementation and interpretation of wireless vibration monitoring data require skilled personnel, which can be a challenge for industries with limited technical expertise.

Regional Insights

- North America – The region dominates the market due to strong adoption of IIoT, increasing investments in predictive maintenance, and a highly developed industrial sector. The U.S. leads with major players offering advanced wireless monitoring solutions.

- Europe – Countries such as Germany, the UK, and France are driving market growth, supported by the presence of leading manufacturing and automotive industries, along with strong regulatory emphasis on workplace safety.

- Asia-Pacific – The fastest-growing market, fueled by rapid industrialization, increasing automation in manufacturing, and rising demand for cost-effective predictive maintenance solutions. China, India, and Japan are key contributors.

- Latin America & Middle East & Africa – These regions are witnessing gradual adoption, with industries such as oil & gas, mining, and energy exploring wireless vibration monitoring to enhance operational efficiency and reduce downtime.

Read Also: Robotics Technology Market