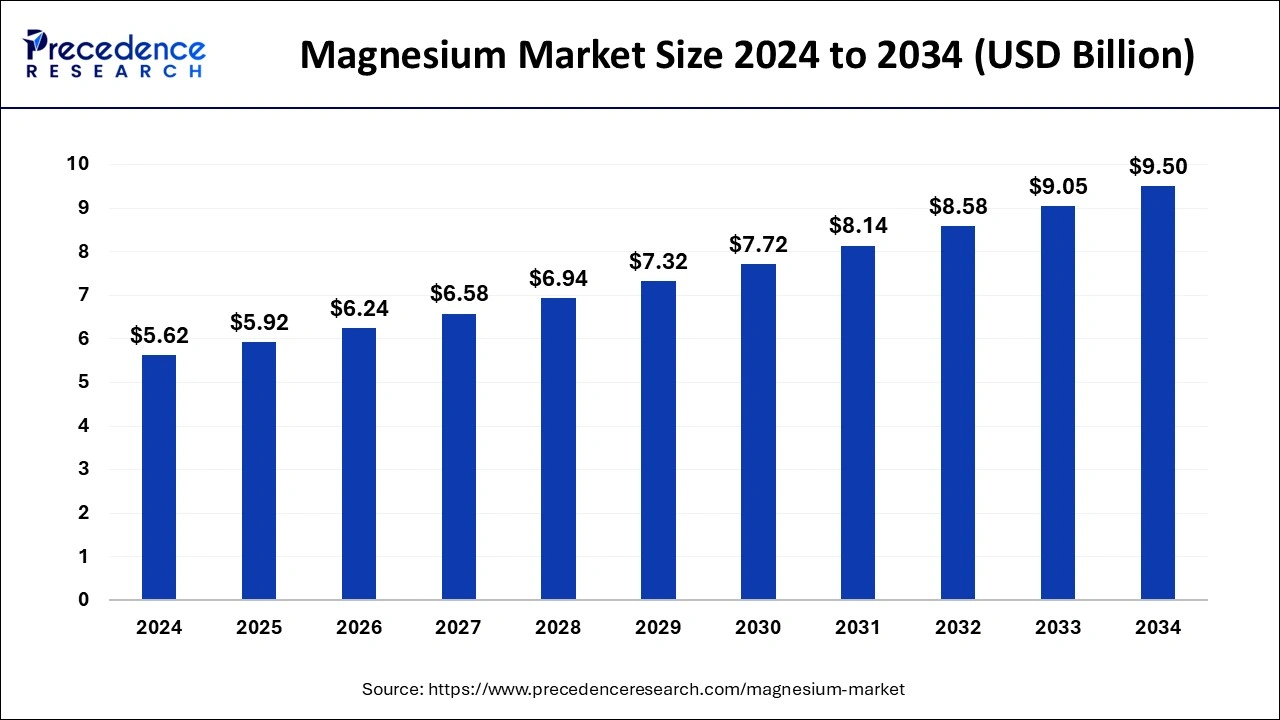

The global magnesium market size surpassed USD 5.33 billion in 2023 and is predicted to be worth around USD 9.05 billion by 2033, growing at a CAGR of 5.44% from 2024 to 2033.

Key Points

- Asia Pacific dominated the market with the largest market share of 35% in 2023.

- Europe is projected to witness significant growth in the market over the estimated period.

- By application, the aluminum alloying segment dominated the market in 2023

- By application, the die casting segment is anticipated to witness substantial growth during the forecast period.

The global magnesium market has experienced steady growth in recent years, driven by its versatile applications across various industries such as automotive, aerospace, electronics, and healthcare. Magnesium, a lightweight metal with excellent strength-to-weight ratio and corrosion resistance, finds extensive use in the production of alloys, die-casting components, and as a reducing agent in various chemical processes. The market encompasses a wide range of products including magnesium ingots, alloys, compounds, and powders, catering to diverse industrial needs. Factors such as urbanization, industrialization, technological advancements, and increasing awareness of lightweight materials for fuel efficiency and sustainability are propelling the growth of the magnesium market worldwide.

Get a Sample: https://www.precedenceresearch.com/sample/4047

Growth Factors:

Several key factors are driving the growth of the global magnesium market. Firstly, the automotive industry represents a significant end-user of magnesium, with increasing demand for lightweight materials to improve fuel efficiency, reduce emissions, and enhance vehicle performance. Magnesium alloys offer substantial weight savings compared to traditional materials such as steel and aluminum, making them ideal for applications in automotive components such as engine blocks, transmission cases, and structural components. Additionally, the aerospace industry utilizes magnesium alloys for aircraft components due to their high strength-to-weight ratio and resistance to fatigue and corrosion. Furthermore, advancements in magnesium production technologies, such as the development of more energy-efficient extraction methods and recycling processes, have improved the cost-effectiveness and sustainability of magnesium production, driving market growth.

Region Insights:

The global magnesium market exhibits regional variations in terms of production, consumption, and market dynamics. China dominates the global magnesium market, accounting for a significant share of both production and consumption. China’s abundant reserves of magnesium resources, coupled with its manufacturing capabilities and low production costs, have positioned it as a key player in the global magnesium market. Other regions such as North America, Europe, and Asia-Pacific also contribute to the magnesium market, driven by demand from industries such as automotive, aerospace, electronics, and construction. The Middle East and Africa region is witnessing growing investment in magnesium production, driven by increasing industrialization and infrastructure development.

Trends:

Several trends are shaping the evolution of the global magnesium market. One prominent trend is the increasing use of magnesium alloys in lightweighting applications across various industries. As industries seek to reduce weight, improve fuel efficiency, and meet stringent regulatory requirements, there is growing demand for magnesium alloys in automotive, aerospace, and electronics applications. Moreover, technological advancements in magnesium processing, such as alloy development, casting techniques, and surface treatments, are enabling the production of complex magnesium components with enhanced mechanical properties and surface finishes. Another trend is the growing adoption of magnesium-based biomedical implants and devices due to their biocompatibility, corrosion resistance, and mechanical properties, offering new opportunities for magnesium manufacturers in the healthcare sector.

Magnesium Market Scope

| Report Coverage | Details |

| Growth Rate from 2024 to 2033 | CAGR of 5.44% |

| Global Market Size in 2023 | USD 5.33 Billion |

| Global Market Size in 2024 | USD 5.62 Billion |

| Global Market Size by 2033 | USD 9.05 Billion |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Magnesium Market Dynamics

Drivers:

Several drivers are driving the demand for magnesium worldwide. Firstly, the automotive industry’s emphasis on lightweighting to improve fuel efficiency and reduce emissions is a significant driver of magnesium demand. Magnesium alloys offer weight savings of up to 75% compared to steel, making them a preferred choice for automotive manufacturers seeking to meet regulatory standards and consumer demands for fuel-efficient vehicles. Additionally, the aerospace industry’s demand for lightweight materials for aircraft components, coupled with the growing trend towards electrification and hybridization in the automotive sector, is driving the adoption of magnesium alloys for structural and non-structural applications. Moreover, the increasing use of magnesium in electronics manufacturing, particularly in smartphones, laptops, and consumer electronics, is fueling demand for high-purity magnesium alloys with excellent electrical and thermal conductivity properties.

Opportunities:

The global magnesium market presents numerous opportunities for stakeholders across the value chain. Magnesium producers have the opportunity to capitalize on the growing demand for lightweight materials in automotive, aerospace, and electronics applications by investing in research and development to enhance the performance, cost-effectiveness, and sustainability of magnesium alloys. Moreover, expanding into emerging applications such as biomedical implants, renewable energy systems, and additive manufacturing presents new growth opportunities for magnesium manufacturers. Furthermore, partnerships and collaborations with end-users, research institutions, and government agencies can accelerate innovation and market penetration for magnesium products. Additionally, investments in recycling technologies and sustainable practices can further enhance the environmental credentials of magnesium production and strengthen market competitiveness.

Challenges:

Despite the opportunities, the global magnesium market faces several challenges that could impact its growth trajectory. One of the primary challenges is the volatility of magnesium prices, which are influenced by factors such as raw material costs, energy prices, and market dynamics. Fluctuations in prices can affect profit margins for magnesium producers and create uncertainty for consumers and investors. Additionally, environmental concerns related to magnesium production, such as energy consumption, emissions, and waste disposal, pose challenges for sustainable magnesium manufacturing. Addressing these challenges will require investment in cleaner production technologies, resource efficiency, and circular economy initiatives to minimize the environmental footprint of magnesium production. Furthermore, competition from alternative materials such as aluminum, carbon fiber, and advanced polymers could pose challenges to the widespread adoption of magnesium in certain applications, necessitating continuous innovation and differentiation to maintain market relevance.

Read Also: Electric Construction Equipment Market Size, Trends Report by 2033

Recent Developments

- In February 2023, Western Magnesium Corporation announced its plan to build a new production facility for magnesium metal with an initial annual capacity of 25,000 metric tons and a new research and development center in Nevada. With the help of this new production facility, the company aims to serve automotive, aerospace, airline, eco-friendly technology companies, and defense contractors through this expansion.

- In July 2022, Chongqing Boao Magnesium-Aluminum Metal Manufacturing Co. Ltd (a wholly owned subsidiary of RSM Group/ Nanjing Yunhai Special Metals Co. Ltd) announced the completion of a high-performance magnesium-aluminum alloy and deep processing project (Phase II project) located in Pingshan Industrial Park, Chongqing City. The new production facilities could have various workshops, including a magnesium particle production workshop with a 7,200 tons/year capacity.

- In January 2022, VSMPO-AVISMA Corporation (VSMPO) announced the extension of a long-term agreement with Barnes Aerospace (Barnes) until December 2026, with an approximate value of $35M. Under the amended contract, VSMPO intends to provide Barnes with an agreed-upon range of alloys and sizes of titanium mill products to support their commercial aircraft manufacturing programs.

- In April 2022, Western Magnesium Corporation announced a non-brokered private placement of USD 3,000,000 in principal amount of unsecured convertible notes.

Magnesium Market Companies

- U.S. Magnesium LLC

- Mag Specialties Inc.

- RIMA Group

- China Magnesium Corporation Ltd.

- Taiyuan Tongxiangyuan Fine Material Co., Ltd.

- POSCO Magnesium Corporation

- Norsk Hydro ASA

- Dead Sea Magnesium Ltd.

- Wenxi YinGuang Magnesium Industry (Group) Co., Ltd.

- Yinguang Magnesium Industry (Group) Co., Ltd.

- Shanxi Wenxi Hongfu Magnesium Co., Ltd.

- Taiyuan Yiwei Magnesium Co., Ltd.

- Shanxi Credit Magnesium Co., Ltd.

- Shanxi Fugu Tianyu Mineral Industry Co., Ltd.

- Shanxi Xinghua Magnesium Co., Ltd.

- Shanxi Yinguang Huasheng Magnesium Co., Ltd.

- Solikamsk Magnesium Works OAO (SMW)

- Timminco Limited

- Ningxia Hui-Ye Magnesium Marketing Group Co., Ltd.

- JSC Magnezit Group

Segments Covered in the Report

By Application

- Aluminum Alloying

- Die casting

- Desulfurization

- Metal Reduction

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.uswebwire.com/