Plate and Frame Heat Exchanger Market Size, Share, Report by 2034

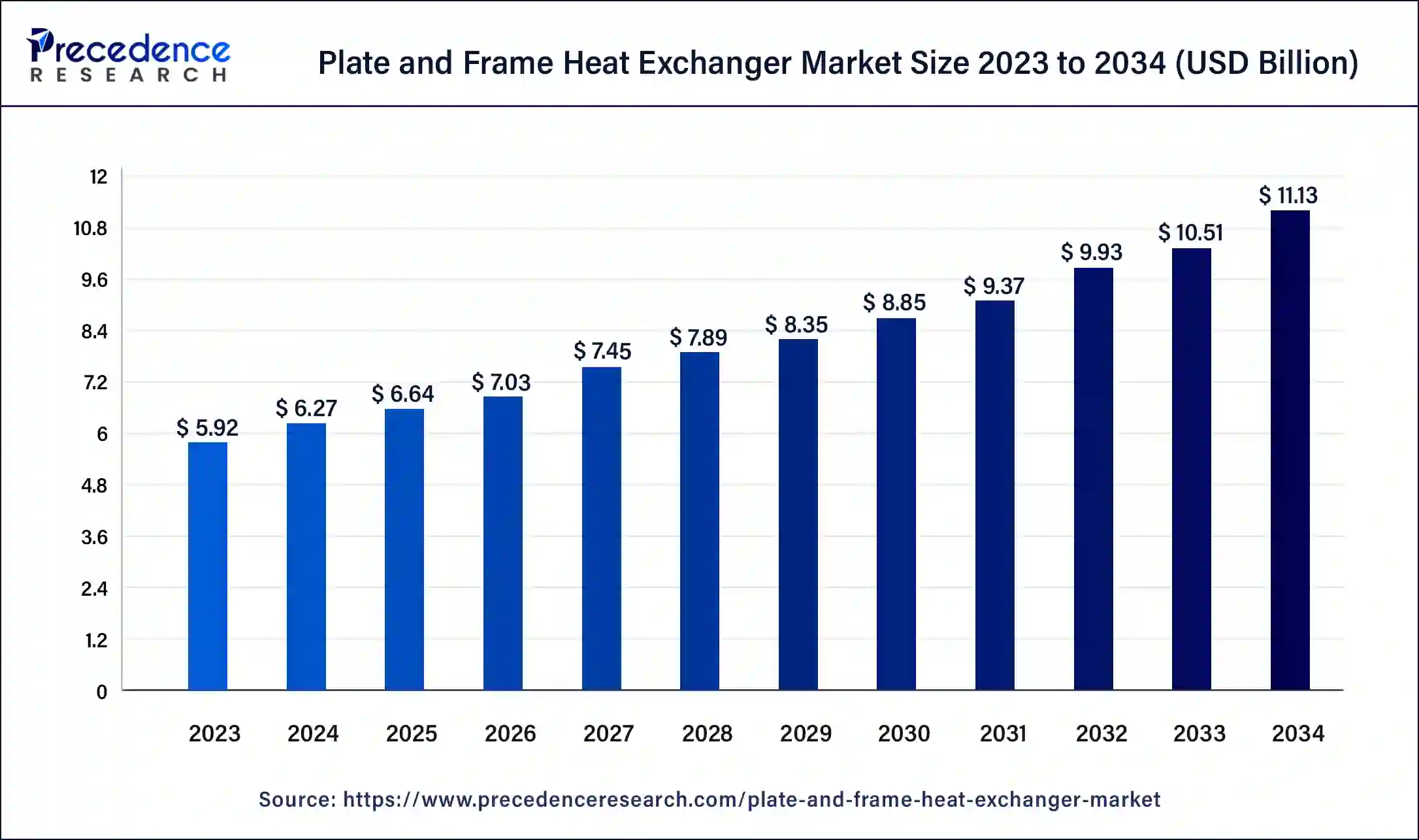

The global plate and frame heat exchanger market size reached USD 5.92 billion in 2023 and is predicted to surpass around USD 11.13 billion by 2034 with a CAGR of 5.91% from 2024 to 2034.

The Plate and Frame Heat Exchanger (PFHE) market has witnessed consistent growth over the past few years, driven by the increasing demand for efficient heat transfer solutions across multiple industries such as chemical processing, power generation, HVAC (heating, ventilation, and air conditioning), food and beverage, and pharmaceuticals. PFHEs are favored for their ability to provide high heat transfer efficiency, compact design, easy maintenance, and flexibility in handling both liquids and gases. They consist of thin plates that are arranged in a frame, creating parallel channels for fluid flow. This design optimizes heat transfer by allowing large surface areas in a small footprint, making them ideal for applications requiring space-saving and cost-efficiency.

Plate and Frame Heat Exchanger Market Key Takeaways

- Asia Pacific dominated the plate and frame heat exchanger market with the largest market share of 42% in 2023.

- North America is projected to host the fastest-growing market in the coming years.

- By type, the gasket segment held a dominant presence in the market in 2023.

- By type, the brazed segment is expected to grow at the fastest rate in the market during the forecast period of 2024 to 2034.

- By application, the HVAC & refrigeration segment accounted for a considerable share of the market in 2023.

- By application, the food & beverages segment is anticipated to grow with the highest CAGR in the market during the studied years.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 11.13 Billion |

| Market Size in 2024 | USD 6.27 Billion |

| Market Growth Rate from 2024 to 2034 | CAGR of 5.91% |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Type, Application, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Plate and Frame Heat Exchanger Market Dynamics

Market Drivers

Several factors are propelling the growth of the PFHE market. One of the key drivers is the growing industrialization and urbanization across the globe, particularly in emerging economies. The need for energy-efficient systems in industries like oil & gas, chemical, and power generation is fostering the adoption of PFHEs, as they help reduce energy consumption and operational costs. Additionally, the increasing focus on sustainability and stringent government regulations concerning energy efficiency and emissions control are encouraging industries to adopt advanced heat exchanger technologies. PFHEs are also increasingly used in renewable energy applications, such as geothermal and solar power plants, which further boosts market growth.

Market Restraints

Despite the positive market outlook, certain factors may hinder the growth of the PFHE market. The initial high cost of plate and frame heat exchangers, particularly for large-scale industrial applications, can be a barrier for small and medium-sized enterprises. Additionally, PFHEs may not be suitable for all applications, especially those involving highly viscous fluids or fluids containing large particles, as this can lead to fouling or clogging of the plates. Furthermore, the complex design and maintenance requirements of certain high-performance PFHE models could limit their adoption in industries where simpler solutions are preferred. Competition from alternative heat exchanger technologies, such as shell and tube heat exchangers, also poses a challenge to market expansion.

Market Opportunities

The PFHE market offers substantial opportunities, especially with advancements in material science and manufacturing technologies. The development of corrosion-resistant materials, such as stainless steel and titanium, has broadened the application scope of PFHEs in industries that handle aggressive chemicals and high-temperature processes. Moreover, the rising demand for renewable energy systems, combined with the increasing focus on waste heat recovery, presents significant growth opportunities. Innovations in modular designs and automation, making PFHEs more adaptable and easier to install, are also driving opportunities in industries focused on upgrading and modernizing their equipment.

Read Also: Paralleling Switchgear Market Size to Touch USD 4.31 Bn by 2034

Regional Insights

Geographically, the PFHE market is segmented into key regions such as North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Asia-Pacific dominates the market, driven by rapid industrialization, urbanization, and infrastructure development in countries like China and India. The region’s growing power generation, chemical, and HVAC industries are major consumers of PFHEs. North America is also a significant market due to stringent regulations on energy efficiency and emissions in the U.S. and Canada. Europe follows closely, with a strong focus on energy conservation and the presence of advanced manufacturing industries. Meanwhile, the Middle East & Africa and Latin America are expected to witness steady growth, driven by the oil & gas and energy sectors in the Middle East and industrial expansion in Latin America.

Plate and Frame Heat Exchanger Market Companies

- Alfa Laval AB

- API Heat Transfer

- Barriquand Group

- Danfoss

- Elanco Heat Transfer Systems

- Gooch Thermal Systems, Inc.

- HFM

- Hisaka Works Limited

- Kelvion Holding GmbH

- Kinam Engineering Pvt. Ltd.

- Nexson Group

- Shineheat Corp.

- SPX Flow

- Tranter, Inc.

- WCR, Inc.

Recent Developments

- In August 2024, SPX FLOW introduced its FastFrame series of plate heat exchangers designed specifically for the food and beverage industries. This innovative technology enhances operational efficiency by significantly reducing the cleaning time of heat exchangers from hours to minutes, thus increasing production capabilities. The Fast Frame series employs a unique design that allows for easier disassembly and reassembly, promoting faster maintenance and minimal downtime.

- In January 2024, Alfa Laval launched the TS45, which is being touted as the world’s most modern gasket plate heat exchanger. This model incorporates innovative features such as the OmegaPort design, which increases thermal efficiency by expanding the thermal surface area, and FlexFlow technology, which optimizes thermal performance by reducing fouling. The TS45 is designed not only to enhance operational efficiency but also to promote sustainability by minimizing energy consumption and reducing carbon emissions across various applications.

Segments Covered in the Report

By Type

- Brazed

- Welded

- Gasketed

- Others

By Application

- Chemicals

- Petrochemicals, Oil & Gas

- Hvac & Refrigeration

- Power Generation

- Pulp & Paper

- Food & Beverages

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa