Sheet Metal Market Size to Worth USD 524.27 Bn by 2033

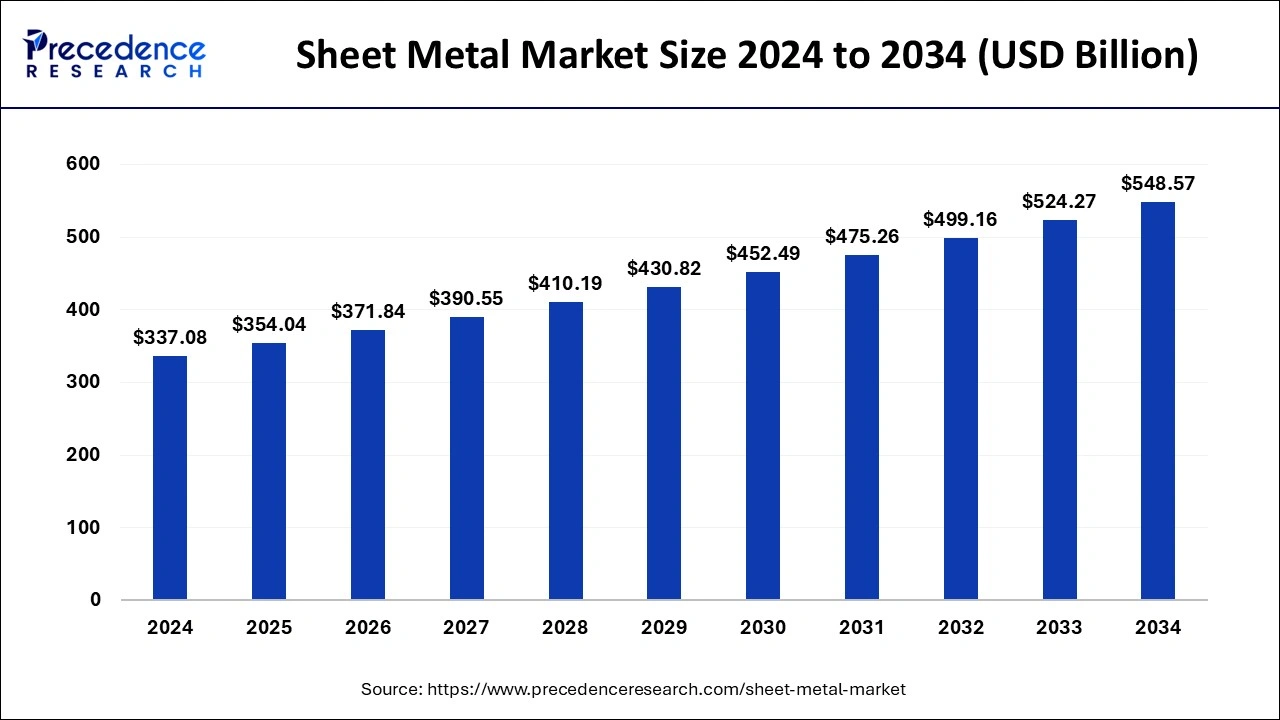

The global sheet metal market size is expected to increase USD 524.27 billion by 2033 from USD 320.94 billion in 2023 with a CAGR of with a CAGR of 5.03% between 2024 and 2033.

Key Points

- Asia Pacific dominated the market with the largest revenue share of 62% in 2023.

- North America is estimated to expand at a CAGR of 4.8% during the forecast period of 2024-2033.

- By material type, the steel segment has held a major revenue share of 93% in 2023.

- By material type, the aluminum segment is expected to be the fastest-growing during the forecast period.

- By end-use type, the building and construction segment has contributed more than 56% of revenue share in 2023.

- By end-use type, the automotive and transportation segment is anticipated to be the fastest growing during the forecast period.

The sheet metal market encompasses a diverse range of industries and applications where thin metal sheets are utilized for various purposes such as automotive manufacturing, construction, aerospace, electronics, and consumer goods. Sheet metal, typically made from steel, aluminum, or other metals, plays a crucial role in modern manufacturing due to its versatility, durability, and cost-effectiveness. The market is driven by the demand for lightweight materials, advancements in manufacturing technologies, and the increasing need for efficient and sustainable production processes across different sectors.

Get a Sample: https://www.precedenceresearch.com/sample/4465

Growth Factors

Several factors contribute to the growth of the sheet metal market. Firstly, the automotive industry is a major driver, with sheet metal being extensively used in car bodies, chassis, and other components to reduce weight and improve fuel efficiency. Additionally, the construction sector utilizes sheet metal for roofing, cladding, and structural components due to its strength and corrosion resistance. The aerospace industry also demands high-performance sheet metal for aircraft structures, interiors, and engine components, driven by stringent safety and performance standards. Moreover, advancements in sheet metal forming technologies, such as laser cutting, CNC machining, and 3D printing, enhance manufacturing precision and flexibility, thereby expanding market opportunities.

Trends in the Sheet Metal Market

Several trends are shaping the sheet metal market landscape. One significant trend is the increasing adoption of lightweight materials in automotive and aerospace applications to achieve fuel efficiency and reduce carbon emissions. Sheet metal fabricated from advanced alloys and composites meets these requirements while maintaining structural integrity. Furthermore, there is a growing trend towards automation and robotics in sheet metal fabrication processes, leading to improved production efficiency, reduced labor costs, and enhanced product consistency. Moreover, the rise of smart manufacturing and Industry 4.0 technologies integrates data-driven insights and connectivity into sheet metal production, enabling real-time monitoring, predictive maintenance, and adaptive manufacturing capabilities.

Region Insights

The sheet metal market exhibits regional variations influenced by economic conditions, industrialization levels, and technological advancements. In North America, the market is driven by the robust automotive and aerospace sectors, along with investments in advanced manufacturing technologies. Europe, known for its stringent environmental regulations, emphasizes lightweight materials and sustainable manufacturing practices in the sheet metal industry. Asia-Pacific dominates the market due to rapid industrialization, particularly in countries like China and India, where automotive production and infrastructure development spur demand for sheet metal. Additionally, emerging economies in Latin America and the Middle East are witnessing increased adoption of sheet metal in construction and industrial applications, driven by urbanization and infrastructure projects.

Sheet Metal Market Scope

| Report Coverage | Details |

| Market Size in 2023 | USD 320.94 Billion |

| Market Size in 2024 | USD 337.08 Billion |

| Market Size by 2033 | USD 524.27 Billion |

| Market Growth Rate from 2024 to 2033 | CAGR of 5.03% |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | Material Type, End-Use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Sheet Metal Market Dynamics

Drivers

Several drivers propel the growth of the sheet metal market globally. Firstly, the expanding automotive production and increasing vehicle sales worldwide drive demand for lightweight materials like aluminum and high-strength steel, which offer superior performance and fuel efficiency benefits. Secondly, infrastructure development projects, such as residential and commercial construction, infrastructure renewal, and urbanization, stimulate demand for sheet metal products like roofing, cladding, and structural components. Moreover, technological advancements in sheet metal processing, including CAD/CAM software, robotics, and additive manufacturing, enhance productivity, reduce lead times, and improve product quality, thereby fostering market growth.

Opportunities

The sheet metal market presents several opportunities for growth and innovation. Firstly, the adoption of sustainable manufacturing practices and eco-friendly materials offers opportunities for manufacturers to cater to the growing demand for environmentally responsible solutions in automotive, construction, and aerospace industries. Secondly, the increasing demand for customized and complex-shaped sheet metal components in various applications creates opportunities for companies specializing in precision sheet metal fabrication and prototyping services. Furthermore, the rise of electric vehicles (EVs) and renewable energy sectors necessitates specialized sheet metal solutions for battery enclosures, solar panels, and wind turbines, driving market expansion.

Challenges

Despite the growth prospects, the sheet metal market faces several challenges. Firstly, fluctuations in raw material prices, especially steel and aluminum, impact production costs and profit margins for manufacturers. Secondly, stringent regulatory requirements regarding emissions, safety, and material specifications in automotive and aerospace industries require continuous compliance and adaptation, adding complexity to manufacturing processes. Moreover, global supply chain disruptions, such as trade tensions and logistics challenges, pose risks to supply continuity and operational efficiency in the sheet metal industry.

Read Also: Chemical Catalyst Market Size to Woth USD 61.46 Bn By 2033

Sheet Metal Market Companies

- Constellium

- Kaiser Aluminum

- Alcoa Corporation

- Arconic

- Baosteel Group

- JFE Steel Corporation

- United States Steel

- POSCO

- Nippon Steel Corporation

- Tata Bluescope Steel

- JSW

Recent Developments

- In June 2022, a global leader in industrial metrology solutions, ZEISS, announced the opening of IMTEX 2022, and the flagship exhibition was arranged by IMTMA. The 3- products were launched: COUNTRUA, METROTOM 1, and SURFCOM NEX 200 SD2. They demonstrated a large range of Metrology solutions that help with sheet metal forming.

- In September 2022, a new digital sheet metal forming technology with Figur G15, which has a high-quality surface finish at IMTS, was announced by Desktop Metal. This new technology does not require post-processing like presses, dies, molds, and stamping tools.

Segments Covered in the Report

By Material Type

- Steel

- Aluminum

- Others

By End-Use

- Automotive & Transportation

- Building & Construction

- Industrial Machinery

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.uswebwire.com/