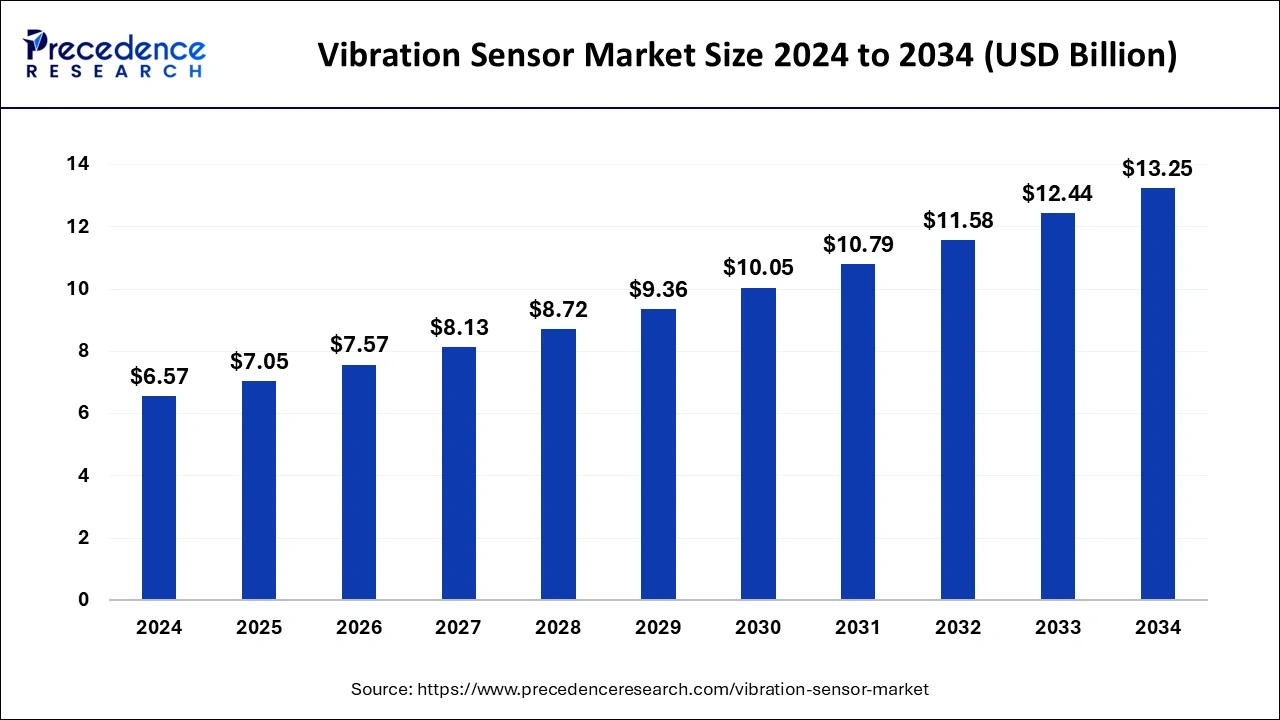

Vibration Sensor Market Size to Attain USD 12.44 Bn by 2033

The global vibration sensor market size surpassed USD 6.12 billion in 2023 and is anticipated to hit around USD 12.44 billion by 2033, growing at a CAGR of 7.35% from 2024 to 2033.

Key Points

- North America dominated the market with the largest market share of 38% in 2023.

- Asia Pacific is expected to witness the fastest CAGR of 8.62% between 2024 and 2033

- By type, the accelerometers segment has captured more than 45% in 2023.

- By type, the displacement sensors segment is expected to expand at a CAGR of 8.4% between 2024 and 2033.

- By technology, the piezoresistive sensors segment has generated 25% of market share in 2023.

- By technology, the tri-axial sensors segment is projected to grow at the fastest CAGR of 8.92% between 2024 and 2033.

- By end-use, the automobile segment has held the significant market share of 28% in 2023.

- By material, the quartz-based sensors segment has recorded more than 44% of the market share in 2023.

The vibration sensor market has witnessed significant growth in recent years, driven by the increasing adoption of vibration monitoring and analysis systems across various industries. Vibration sensors, also known as accelerometers, are devices used to measure the vibration and oscillation of machines, equipment, and structures. They play a crucial role in predictive maintenance, condition monitoring, and fault detection, helping businesses improve operational efficiency, prevent downtime, and reduce maintenance costs. With advancements in sensor technology, data analytics, and wireless connectivity, the vibration sensor market is poised for further expansion, offering lucrative opportunities for manufacturers, service providers, and end-users alike.

Get a Sample: https://www.precedenceresearch.com/sample/3969

Growth Factors:

Several key factors have contributed to the growth of the vibration sensor market. Firstly, the increasing focus on predictive maintenance and asset reliability has driven demand for vibration monitoring solutions across industries such as manufacturing, automotive, aerospace, oil and gas, and healthcare. By detecting early signs of equipment failure and mechanical wear, vibration sensors enable proactive maintenance strategies, minimizing unplanned downtime and optimizing asset performance.

Moreover, technological advancements in sensor design, miniaturization, and wireless connectivity have made vibration sensors more compact, reliable, and cost-effective. The integration of microelectromechanical systems (MEMS) technology and advanced signal processing algorithms has improved the accuracy and sensitivity of vibration sensors, enabling real-time monitoring and analysis of machine health.

Furthermore, the growing adoption of Industrial Internet of Things (IIoT) and Industry 4.0 initiatives has spurred the deployment of connected sensors and predictive analytics platforms. Vibration sensors play a crucial role in IoT-enabled condition monitoring systems, providing real-time data on equipment health and performance. By leveraging IoT platforms and cloud-based analytics, businesses can optimize maintenance schedules, prioritize critical assets, and improve overall operational efficiency.

Additionally, stringent regulatory requirements and industry standards mandating equipment safety and reliability have driven investments in vibration monitoring solutions. Industries such as aerospace, automotive, and power generation are subject to regulatory compliance and performance standards, necessitating the use of vibration sensors for predictive maintenance and quality assurance.

Furthermore, the increasing adoption of vibration sensors in emerging applications such as structural health monitoring, smart buildings, and wearable devices is expanding the addressable market for sensor manufacturers. Vibration sensors are used to monitor the structural integrity of buildings, bridges, and infrastructure, ensuring safety and preventing structural failures. In the consumer electronics sector, vibration sensors are integrated into fitness trackers, smartwatches, and wearable health devices for activity tracking and gesture recognition.

Region Insights:

The adoption of vibration sensors varies across regions, influenced by factors such as industrialization, technological development, and regulatory environment. In North America, the United States and Canada are leading markets for vibration sensors, driven by the presence of key industries such as manufacturing, automotive, and aerospace. The region’s focus on innovation and technological advancements has led to the widespread adoption of vibration monitoring solutions for predictive maintenance and asset management.

In Europe, countries such as Germany, the UK, and France are prominent markets for vibration sensors, owing to their strong manufacturing base and emphasis on industrial automation. The European Union’s regulations on equipment safety and environmental protection have spurred investments in vibration monitoring technologies, particularly in sectors such as automotive manufacturing, where precision and reliability are critical.

In the Asia Pacific region, countries like China, Japan, and South Korea are witnessing rapid growth in the vibration sensor market, driven by the expansion of manufacturing and automotive industries. China, in particular, is a major manufacturing hub for electronics, automotive, and consumer goods, driving demand for vibration sensors for quality control and production monitoring. Additionally, the region’s growing focus on infrastructure development and urbanization is fueling demand for vibration sensors for structural health monitoring and smart city initiatives.

In Latin America and the Middle East, industries such as oil and gas, mining, and construction are driving demand for vibration sensors to ensure operational safety and equipment reliability. Countries like Brazil, Mexico, Saudi Arabia, and the UAE are investing in vibration monitoring technologies to optimize asset performance and mitigate operational risks in hazardous environments.

Vibration Sensor Market Scope

| Report Coverage | Details |

| Growth Rate from 2024 to 2033 | CAGR of 7.35% |

| Global Market Size in 2023 | USD 6.12 Billion |

| Global Market Size by 2033 | USD 12.44 Billion |

| U.S. Market Size in 2023 | USD 1.74 Billion |

| U.S. Market Size by 2033 | USD 3.55 Billion |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | By Type, By Technology, By End-use, and By Material |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Vibration Sensor Market Dynamics

Drivers:

Several drivers are shaping the growth of the vibration sensor market. One of the primary drivers is the increasing emphasis on predictive maintenance and asset management to improve operational efficiency and reduce downtime. By detecting early signs of equipment failure and mechanical wear, vibration sensors enable proactive maintenance strategies, minimizing unplanned downtime and optimizing asset performance.

Moreover, the growing adoption of Industrial Internet of Things (IIoT) and Industry 4.0 initiatives is driving demand for connected sensors and predictive analytics platforms. Vibration sensors play a crucial role in IoT-enabled condition monitoring systems, providing real-time data on equipment health and performance. By leveraging IoT platforms and cloud-based analytics, businesses can optimize maintenance schedules, prioritize critical assets, and improve overall operational efficiency.

Furthermore, the stringent regulatory requirements and industry standards mandating equipment safety and reliability are driving investments in vibration monitoring solutions. Industries such as aerospace, automotive, and power generation are subject to regulatory compliance and performance standards, necessitating the use of vibration sensors for predictive maintenance and quality assurance.

Additionally, the increasing focus on safety and risk mitigation in hazardous environments such as oil and gas, mining, and chemical processing industries is driving demand for vibration sensors for asset protection and personnel safety. Vibration sensors are used to monitor the health and integrity of equipment, ensuring safe operation and preventing catastrophic failures that could result in accidents or environmental hazards.

Furthermore, the rising adoption of vibration sensors in emerging applications such as structural health monitoring, smart buildings, and wearable devices is expanding the addressable market for sensor manufacturers. Vibration sensors are used to monitor the structural integrity of buildings, bridges, and infrastructure, ensuring safety and preventing structural failures. In the consumer electronics sector, vibration sensors are integrated into fitness trackers, smartwatches, and wearable health devices for activity tracking and gesture recognition.

Opportunities:

The vibration sensor market presents several opportunities for manufacturers, service providers, and end-users. One of the significant opportunities lies in the development of advanced sensor technologies and data analytics solutions to meet the evolving needs of industrial applications. Manufacturers are investing in research and development (R&D) to improve sensor sensitivity, reliability, and durability, enabling more accurate and comprehensive monitoring of machine health.

Moreover, there is growing demand for wireless vibration monitoring solutions that offer remote monitoring capabilities and real-time data access. Wireless sensors eliminate the need for wired connections, enabling flexible deployment and cost-effective scalability. As industries adopt IoT-enabled condition monitoring systems, there is a need for wireless vibration sensors that can seamlessly integrate with existing infrastructure and provide actionable insights for predictive maintenance.

Additionally, there is an opportunity to leverage artificial intelligence (AI) and machine learning algorithms for predictive maintenance and fault detection. By analyzing vast amounts of sensor data and historical maintenance records, AI-powered analytics platforms can identify patterns, anomalies, and early warning signs of equipment failure, enabling proactive maintenance interventions and optimization of asset performance.

Furthermore, there is a growing trend towards integrated monitoring solutions that combine vibration sensors with other sensors such as temperature, pressure, and humidity sensors to provide comprehensive asset monitoring and diagnostics. Integrated sensor systems offer a holistic view of equipment health and performance, enabling more informed decision-making and optimization of maintenance strategies.

Moreover, there is an opportunity to expand into emerging verticals such as smart buildings, smart infrastructure, and wearable devices, where vibration sensors can play a crucial role in ensuring safety, efficiency, and comfort. By developing specialized sensor solutions for these applications, manufacturers can tap into new markets and diversify their product offerings.

Read Also: Cardiac Rhythm Management Devices Market Size, Report by 2033

Recent Developments

- In January 2023, HARMAN International unveiled its sound and vibration sensor and external microphone products, designed to enhance the auditory experience in and around vehicles for various applications, including identifying emergency vehicle sirens and detecting glass breakage or collisions.

- In March 2022, SAMSUNG released the Galaxy A53 5G smartphone, which features an octa-core processor, a 120 Hz refresh rate display, and a sharp resolution of 1080 x 2400 pixels.

- In May 2022, Sensoteq announced the Kappa X Wireless Vibration Sensor. This compact sensor has a replaceable battery and can detect faults, making it suitable for various industrial applications.

Vibration Sensor Market Companies

- Dytran Instruments, Inc.

- PCB Piezotronics, Inc. (IMI Sensors division)

- Hansford Sensors Ltd.

- TE Connectivity Ltd. (formerly Measurement Specialties, Inc.)

- Honeywell International Inc.

- Robert Bosch GmbH

- National Instruments Corporation

- Analog Devices, Inc.

- Meggitt PLC

Segment Covered in the Report

By Type

- Accelerometers

- Velocity Sensors

- Displacement Sensors

By Technology

- Piezoresistive Sensors

- Tri-Axial Sensors

By End-use

- Automotive Sector

- Aerospace And Defense

- Consumer Electronics

By Material

- Quartz-based Sensors

- Doped Silicon Sensors

- Piezoelectric Ceramics

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.uswebwire.com/