Wind Turbine Composite Materials Market Size,Trends, Report By 2033

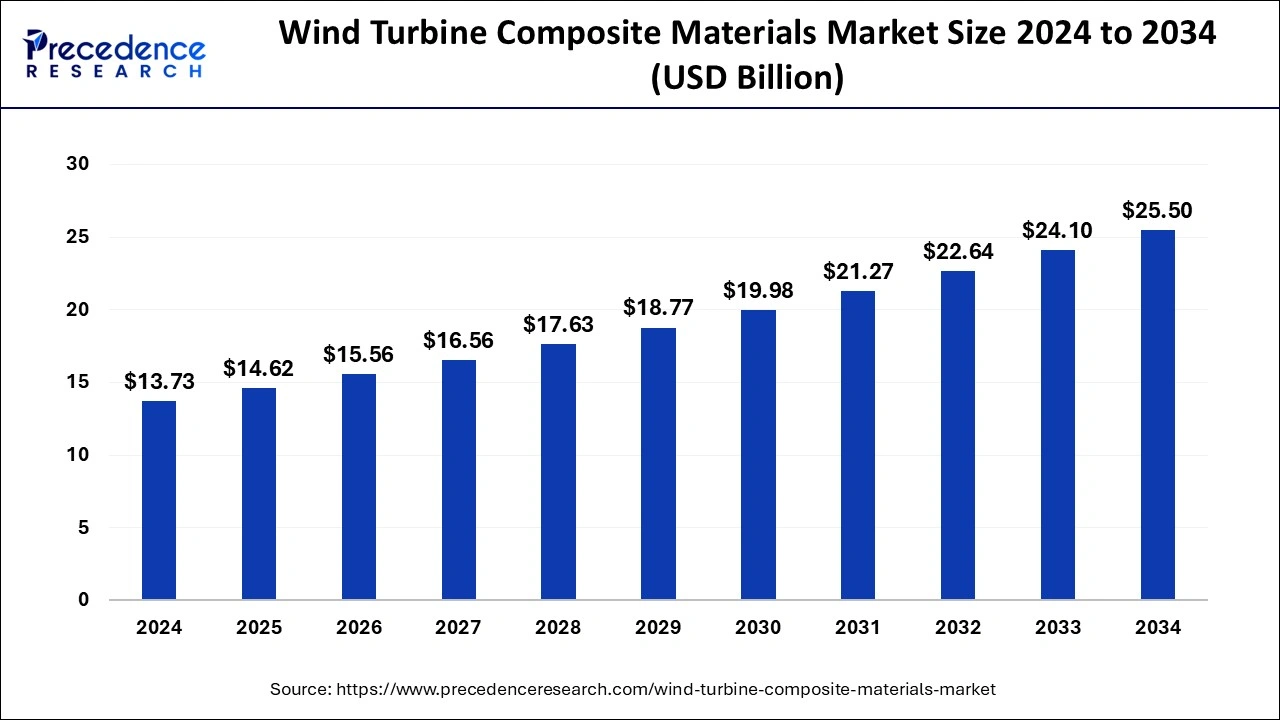

The global wind turbine composite materials market size surpassed USD 12.90 billion in 2023 and is projected to be worth around USD 24.10 billion by 2033, growing at a CAGR of 6.44% from 2024 to 2033.

Key Points

- Asia Pacific dominated the market in 2023 with the largest share 35%.

- North America is anticipated to grow at a notable growth rate in the wind turbine composite materials market during the forecast period.

- By fiber type, the glass fiber segment held the largest share of around 65% in 2023.

- By fiber type, the carbon fiber segment is expected to grow significantly during the forecast period.

- By technology, the vacuum injection molding segment accounted for the dominating share of 45% in 2023.

- By technology, the prepreg segment is observed to witness a considerable growth rate in the global wind turbine composite materials market over the forecast period.

- By application, the wind blades segment held the dominating share of 75% in 2023.

Wind turbine composite materials play a crucial role in the construction and efficiency of modern wind turbines. These materials, typically made from a combination of fiberglass, carbon fiber, epoxy resins, and other additives, offer numerous advantages over traditional materials like steel or concrete. The use of composites in wind turbine blades, nacelles, and other components has become increasingly prevalent due to their lightweight, durable, and corrosion-resistant properties.

Get a Sample: https://www.precedenceresearch.com/sample/4067

Wind Turbine Composite Materials Market Scope

| Report Coverage | Details |

| Growth Rate from 2024 to 2033 | CAGR of 6.44% |

| Global Market Size in 2023 | USD 12.90 Billion |

| Global Market Size in 2024 | USD 13.73 Billion |

| Global Market Size by 2033 | USD 24.10 Billion |

| Largest Market | Asia-Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | By Fiber Type, By Technology, and By Application |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

One of the primary benefits of using composite materials in wind turbines is their lightweight nature. Compared to steel or concrete, composites have a much higher strength-to-weight ratio, meaning they can withstand significant loads while being lighter in weight. This characteristic is particularly advantageous in wind turbine blades, where lighter materials allow for longer blades that can capture more wind energy and generate higher power output.

In addition to being lightweight, wind turbine composite materials also offer exceptional durability and resistance to fatigue. Wind turbine blades are subjected to constant stresses from wind and other environmental factors, making durability a critical consideration. Composites have the ability to flex and bend without undergoing permanent deformation, making them highly resilient to fatigue and extending the lifespan of wind turbine components.

Furthermore, composite materials provide excellent corrosion resistance, particularly in offshore wind applications where turbines are exposed to harsh marine environments. Unlike steel, which can corrode over time when exposed to saltwater and moisture, composites are inherently resistant to corrosion, reducing maintenance costs and extending the operational life of offshore wind farms.

Another advantage of using composite materials in wind turbines is their design flexibility. Composites can be molded into complex shapes and geometries, allowing for optimized aerodynamic profiles and enhanced energy capture. Manufacturers can tailor the properties of composites to meet specific performance requirements, resulting in more efficient and reliable wind turbine systems.

Moreover, the use of composite materials in wind turbines contributes to sustainability and environmental protection. Composites can be manufactured using recycled materials and renewable energy sources, reducing the carbon footprint of wind turbine production. Additionally, the lightweight nature of composites results in lower transportation costs and energy consumption during installation, further enhancing the environmental benefits of wind energy.

Despite these advantages, there are also some challenges associated with wind turbine composite materials. One challenge is the cost of manufacturing high-quality composites, which can be higher than traditional materials like steel or concrete. However, advancements in manufacturing processes and economies of scale are helping to reduce the cost gap and make composites more competitive in the wind energy industry.

Another challenge is the recyclability of composite materials at the end of their lifespan. While composites offer excellent durability and longevity, the recycling infrastructure for composite materials is still relatively underdeveloped compared to traditional materials. Efforts are underway to improve the recyclability of composites and develop sustainable end-of-life solutions to minimize environmental impact.

Read Also: Data Center Transformation Market Size, Share, Report by 2033

Recent Developments

- According to a BSE filing, in June 2023, SJVN Green Energy, a subsidiary of SJVN Ltd, secured a 200 MW wind power project through a tariff-based competitive bidding process conducted by the Solar Energy Corporation of India. This project requires an investment of Rs 1,400 crore. SJVN Green Energy will undertake the development of this wind power project anywhere in India through an EPC (engineering procurement construction) contract.

- Amazon now has more than 500 wind and solar projects globally, and once operational, they are expected to generate more than 77,000 gigawatt-hours (GWh) of clean energy each year, or enough to power 7.2 million U.S. homes.

Wind Turbine Composite Materials Market Companies

- TPI Composites Inc.

- Huntsman International LLC

- Teijin Limited

- TPI Composites Inc.

- LM Wind Power

- Suzlon Energy Limited

- Gurmit Holding AG

- LM Wind Power

- Molded Fiber Glass Companies

- Toray Industries, Inc.

- Vestas Wind Systems A/S

- Siemens Gamesa Renewable Energy, S.A.U.

- Hexcel Corporation

- Lianyungang Zhongfu Lianzhong Composites Group Co. Ltd

- Others

Segments Covered in the Report:

By Fiber Type

- Glass Fiber

- Carbon Fiber

- Others

By Technology

- Vacuum Injection Molding

- Prepreg

- Hand Lay-Up

- Others

By Application

- Wind blades

- Nacelles

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.uswebwire.com/